G&G Reveals Sustainable Practices at its Inkjet Factory

G&G Reveals Sustainable Practices at its Inkjet Factory

The demand for sustainable products is growing at an unprecedented rate. End-users and consumers are demanding greener solutions as they become more aware of the importance of protecting the environment.

According to one report, there has been a 71% increase in global internet searches for sustainable goods in recent years.

G&G’s customers can trust the sustainable, remanufactured inkjet cartridges being offered because G&G’s commitment to the environment is not just “talk.”

Here are some of the real, visible green practices and operations implemented by G&G to protect the environment.

G&G uses an extensive array of photovoltaic cells on the roofs of its factories to power the plant from the sun. There are 12,000 square meters of solar panels that capture this clean energy. When the weather is good, up to 300,000 kW of photovoltaic power can be generated each month, providing nearly 10% of the plant’s total electricity needs.

Many ink cartridge remanufacturers create water pollution as they clean out the waste inks from the used cartridges, before refilling them. This cannot be defined as a “green” product. G&G has invested US$1.25 million in a 1,500 square meter sewage treatment station. Eight hundred cubic meters of sewage are processed each day, mostly from residual ink captured from cleaning used OEM cartridges for remanufacturing. The project converts dirty and waste water into clean water that can be used to water the flowers and gardens on G&G’s

Zhuhai campus.

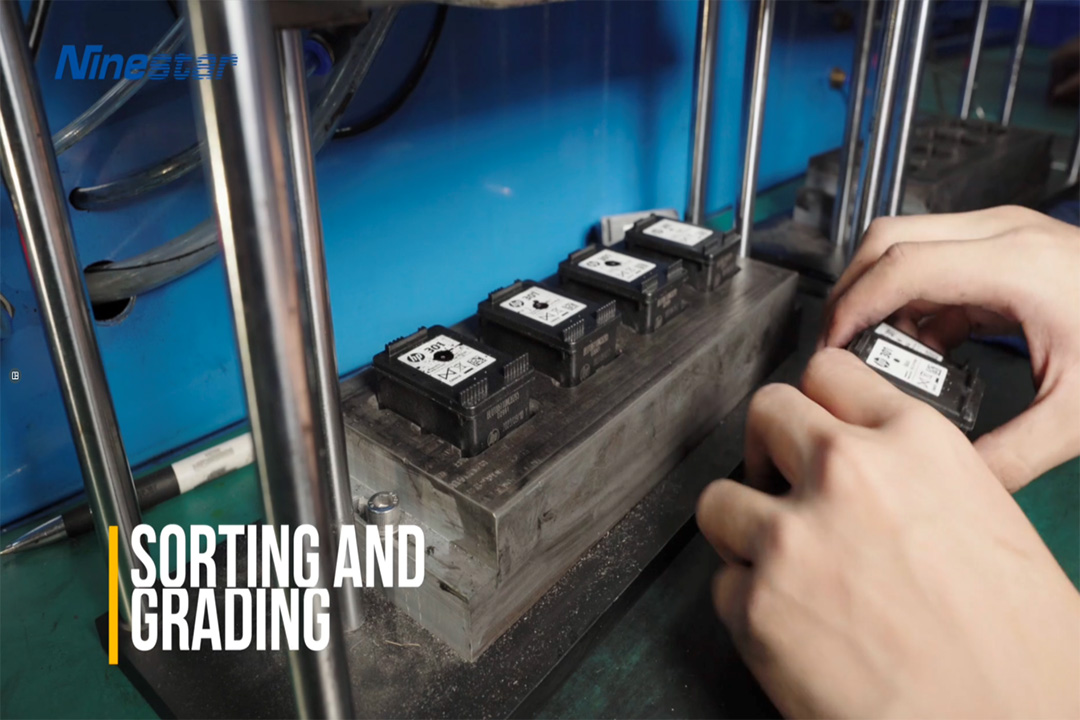

Selected Sorting & Grading Processes

G&G’s remanufacturing process begins with a strong empties collection program. More than 750,000 cartridges from collection agencies around the world arrive at the 12,000 square metre warehouse each month. Professionally trained technicians sort and grade the empties in compliance with rigorous empty cartridge standards.

Smart Remanufacturing Lines

After being sorted and graded, each inkjet cartridge is cleaned by G&G’ tailor-made, automated production line. This increases efficiency by 20% and saves up to 65% of the water that would have been used by traditional means, which is a green initiative in itself.

About Ninestar & G&G

For over two decades, Ninestar has been recognized as the leading firm in the third-party supplies industry thanks to its commitment to innovation. Since 2000, Ninestar has invested extensively in abilities to quickly bring to market the industry’s technologically advanced products. Today, Ninestar’s G&G-branded products are recognized around the world for their superior performance and reliability.

© Ninestar Image Tech Limited. All rights reserved worldwide. All other brand and product names are trademarks or registered trademarks of their respective companies.

Related:

- G&G Releases Toner Cartridges for Kyocera Printers

- Ninestar Net Profit Grows 102.49% in H1

- G&G Continues to Optimize its HP & Canon Patented Solutions

- G&G Releases Solutions for Konica Minolta Printers

- Ninestar Receives Green Sustainable Award

Comment:

Please leave your comments below for the story .

Leave a Comment

Want to join the discussion?Feel free to contribute!