G&G Reveals How it Perfectly Matches Epson’s Print Head

G&G Reveals How it Perfectly Matches Epson’s Print Head

It is well recognized that the print head plays an important role in obtaining the best printing performance. Only those ink cartridges that can perfectly match the print head are the best choice for consumers. G&G has researched its own solution and has made a great breakthrough in its Epson series of ink products.

G&G rigorously keeps track of the latest new technologies being developed by printer manufacturers (OEMs). Being “in the shadow of the OEMs” has given G&G the ability to respond quickly to ground-breaking products to meet market demands.

Epson first launched its PrecisionCore printing technology ten years ago. It is one of the OEM’s most core and essential technologies.

According to Epson, its PrecisionCore printheads are very difficult to manufacture. The OEM claims the manufacture and assembly of MicroTFP print chips, the devices at the heart of these printheads, require three innovative technologies that only Epson possesses. These are its thin-film piezo, MEMS, and its ultra-precision assembly technologies.

The latest Epson PrecisionCore technology, also called heat-free technology, has increased print speed and productivity. This latest innovation has set up some technical barriers for third-party manufacturers.

Over the years, G&G has been consistently focused and dedicated to researching and updating its own ink solutions to continuously meet the high bar set by each update of Epson’s PrecisionCore technology.

Many have asked how G&G overcame the challenges and how it designed its own ink solutions. These can now be revealed.

- Analyzes OEM’s ink systems

G&G analyzes the ratio of solvent and water of the OEM’s ink color paste, concerning the original ink system. In this way, G&G can ensure its ink can print smoothly with the PrecisionCore printing head without clogging.

- Refers to OEM’s ink parameters

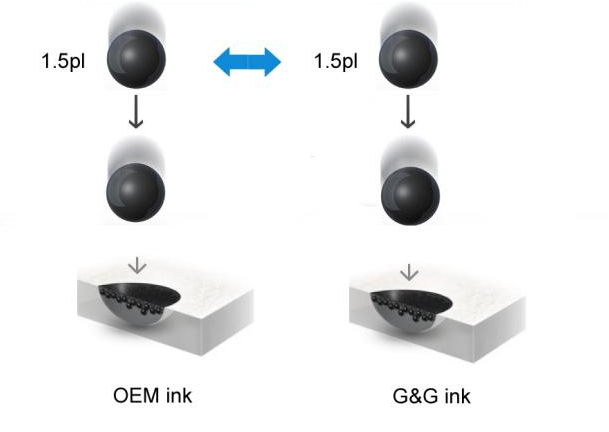

G&G adjusts the ink tension and viscosity based on the parameters of OEM’s ink. This ensures that the size of the ink drop is consistent with that of the original, while also maintaining the same size of the ink drop as the original. As a result, the color performance of the printed pages using G&G’s inks is equivalent to the OEM.

- Develops fast-drying ink solution

G&G uses fast-drying ink solvents that allow the ink to dry quickly on the paper. In addition, the G&G ink is scratch-resistant, has low penetration, and has high color density, resulting in clear and sharp text without being faint.

- Adopts high-quality raw materials

G&G has been collaborating with well-known international raw materials distributors, including Cabot and EVA, for more than two decades. This guarantees that G&G’s inks can always be of the highest quality. Therefore, G&G is confident that it can deliver outstanding ink printing performance with a wide color gamut and vivid colors.

- Utilizes state-of-the-art ink filtration technology

G&G’s partnerships with leading, cutting-edge partners. This allows G&G access to nano-level, four-layer filtration processes to prevent impurities. Ink quality has been optimized to the greatest extent so that it can be comparable with the OEM.

For more than 20 years, G&G has developed novel and innovative ink technologies to provide the best printing experience for end users. At the same time, it remains competitive and profitable. Today, G&G’s inks are being successfully sold and used in many key markets around the world including Europe, Asia and South America.

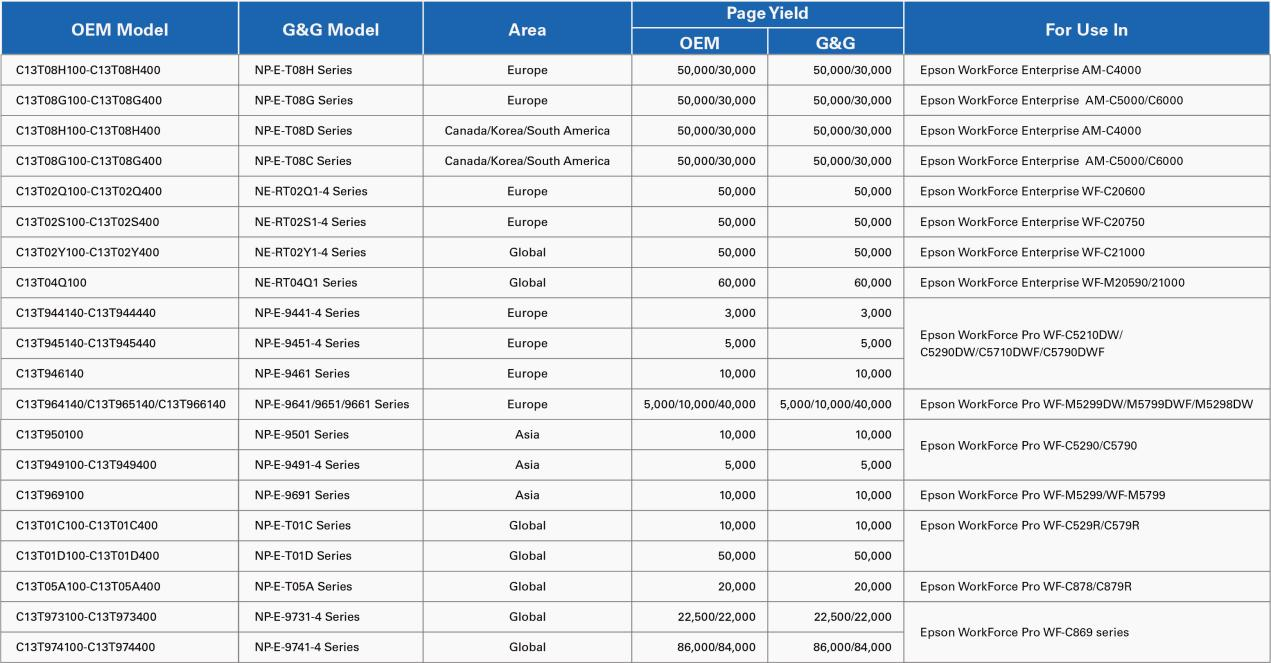

Specifics

For more information, please contact info@ggimage.com.

Related:

- G&G Releases Patented Ink Bottles for Use in Epson Printers

- G&G Releases Replacement Toner Cartridges for Brother Printers

- G&G to Release its Patented Ink Cartridges for Use in Epson Series

- G&G Patented Ink Pack Solution for Use in Epson Series

- G&G Introduces Patented Refill Ink Bottles to Help Boost Online Sales

Leave a Comment

Want to join the discussion?Feel free to contribute!