New Opportunities to Remanufacture New-Build Cartridges

New Opportunities to Remanufacture New-Build Cartridges

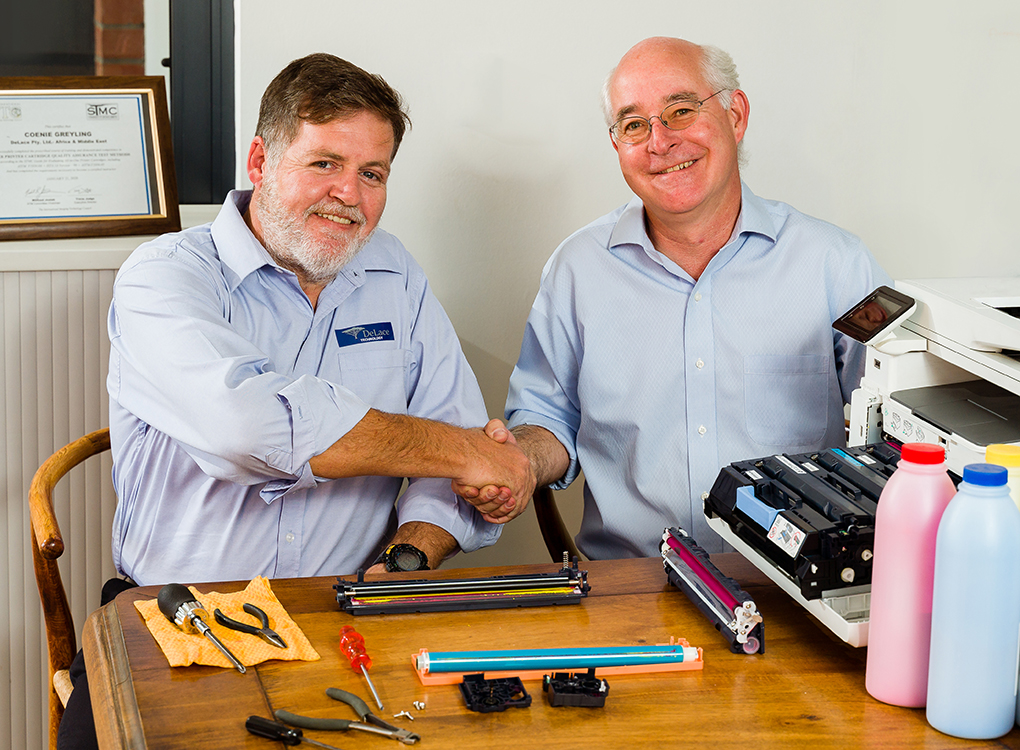

Coenie Greyling and business partner Stuart Lacey shake hands on new reman business opportunities that could reach a billion people on the African continent.

It is often said that Africa is not for the faint-hearted and not for sissies. This is true for so many reasons but despite its intrinsic and inherent problems, it is a continent brimming with so many opportunities for growth and expansion.

The immense historical success of the remanufacturing industry, obviously opposed by the OEMs (Original Equipment Manufacturers), opened an obvious market opportunity for the New-Build Cartridge (NBC) manufacturers. In fact, the incredible success story of the remanufacturing industry, worldwide, in taking market share from the OEM’s, has ultimately led to its very unfortunate demise.

In the pioneering days, it was humbling to see the exceptional ingenuity and resourcefulness of companies, with little or no technical support from compatible imaging suppliers and manufacturers. There were none. For those that can remember the frustration of desperately seeking some sort of toner that would work in the first 92285A (CX) cartridge and then the delight of making available a choice of consumables for the 95A (SX). That competence and resourcefulness continue to exist in the marketplace.

The incredible success and growth of the NBC manufacturers have enabled them to take more and more of both the OEM and remanufactured consumables market. It ultimately led to one aftermarket company purchasing an OEM, a true testament to the ultimate success of compatible products.

The incredible success and growth of the NBC manufacturers have enabled them to take more and more of both the OEM and remanufactured consumables market. It ultimately led to one aftermarket company purchasing an OEM, a true testament to the ultimate success of compatible products.

However, the success of the NBCs has come at the cost of losing so many incredibly resourceful companies and people from the remanufacturing industry. It has decimated localised production with the loss of thousands of jobs.

NBC pricing has simply made it unprofitable for specialised manufacturers of components to survive and the vast majority of companies who were remanufacturing have either now closed shop or are now offering NBC products instead. They simply could not be competitive enough. It also became more and more difficult to source the required components for remanufacturing.

The African market is turning its back on cheap, low-quality products and is maturing into a market looking for and even demanding the highest quality product that delivers on expectations.

Africa has been brought back into the spotlight and is being seen by many as the last frontier for business growth opportunities. Even more relevant is the understanding that local manufacturing will be key to success on the continent.

The African Continental Free Trade Agreement (AfCFTA) came into effect on January 1, 2021, and the world’s largest single market was formed.

Trade internally, between African markets, has been lower than in any other region in the world with less than 18 percent of exports traded within the continent. Intra-European trade is as high as 70%. The African Union, through the AfCFTA Agreement, aims to generate economic growth, create jobs and

make Africa a meaningful player in international trade. It is estimated that intra-African trade will increase by 52 percent by 2022, primarily driven by locally produced products.

The African continent has seen more than its fair share of substandard, cheap NBC’s flooding into the various markets from unknown and untested sources with the only intent of making quick money and no intention of creating a long term, sustainable business.

But the African market is turning its back on cheap, low-quality products and is maturing into a market looking for and even demanding the highest quality product that delivers on expectations. And the demand is for locally manufactured products.

Here lies the opportunity

With the new agreement in place and the drive for locally produced products, we will see trade barriers implemented to promote the intra-Africa trade at the expense of imported products. The road to economic recovery, post-Covid-19 will accentuate this trend.

The aftermarket was built on the ability to take a used OEM supply, opening the casing, renewing and replacing the components into a reassembled and tested unit of a recognised brand with quality built into the unit through dedication and experience.

Africa has been brought back into the spotlight and is being seen by many as the last frontier for business growth opportunities.

In part, the demise of the remanufacturing sector was a drawback and the unsuitability of remanufacturing the NBC cartridge and finding a tested solution for servicing the unit.

For a moment, imagine an NBC solution in the form of a cartridge service kit removing the intrinsic difficulties of remanufacturing, nay, servicing of the unit.

Often the quality of the plastic used in the casing, stability of attached blades and foams and the difference in the component dimensions precluded NBC cartridges from being remanufactured.

For Africa, the vision would be a recyclable NBC cartridge. A cartridge of sufficient build quality where secondary components and the casing will last an additional cycle or two. Fear should not be a factor for the brave embarking on this new potential and the quality of the NBCs is improving hand over fist. We certainly see cartridges today that could easily be re- serviced if a full kit was made available and the correct training provided. Closing the economical loop is possible.

The vision of having preassembled components including OPC drum, PCR, chip, developer or magnetic roller with wiper and doctor blades readily packed as a single-for-use pre-packed cartridge service kit evokes questions of merit.

South African-based Stuart Lacey holds a 95A (SX) cartridge popular with remanufacturers in the 1990s.

Allowing this vision would not only allow local in-country remanufacturing but also generate a new revenue stream for the NBC cartridge manufacturers by creating income not only from their cartridge ranges but also the supply of their matched components in a service kit form. In this arena, the quality and stability of components and parts would lead the way. All matched components delivered in a kit form for use in a market-leading NBC manufacturers cartridge should be very feasible in a very short timeframe.

In Africa, the opportunities for such an offering are considerable. I see a new cartridge economy with smaller market participants all competing equally in their territories, with smaller and more quality competitive product not only targeting the OEM but also unsupported NBC cartridges. Building a brand name connected with a quality product is paramount for longevity.

Based in Johannesburg, South Africa, Coenie Greyling is an official STMC trainer throughout Africa. He has a proven record of success in production and remanufacturing environments related to safety, materials management, job planning, quality control and employee and customer training. You can contact Greyling by email.

Based in Johannesburg, South Africa, Coenie Greyling is an official STMC trainer throughout Africa. He has a proven record of success in production and remanufacturing environments related to safety, materials management, job planning, quality control and employee and customer training. You can contact Greyling by email.

You can read the full edition of RT ImagingWorld magazine —containing Coenie Greyling’s article, “New Opportunities to Remanufacture New-Build Cartridges” on page 6.

Related:

- Time to Seize the Opportunity in Africa

- Can Latin America Manufacture its own NBCs—and be Profitable?

- Striving for Into Africa

- HP Fights Counterfeit Cartridges in Africa

- China Looks to Africa for Growth

- Industry Eyes Turn to Africa

Comment:

Please add your comment below about this article, “New Opportunities to Remanufacture New-Build Cartridges” or join the conversation on LinkedIn social media.

Leave a Comment

Want to join the discussion?Feel free to contribute!