Konica Minolta Unveils New Inkjet Printheads

Konica Minolta, Inc. (Konica Minolta) today announced that it has developed three new industrial inkjet printheads that adopt its independently developed MEMS*1 technologies. The mass production is planned to start in the spring of 2016.

Konica Minolta, Inc. (Konica Minolta) today announced that it has developed three new industrial inkjet printheads that adopt its independently developed MEMS*1 technologies. The mass production is planned to start in the spring of 2016.

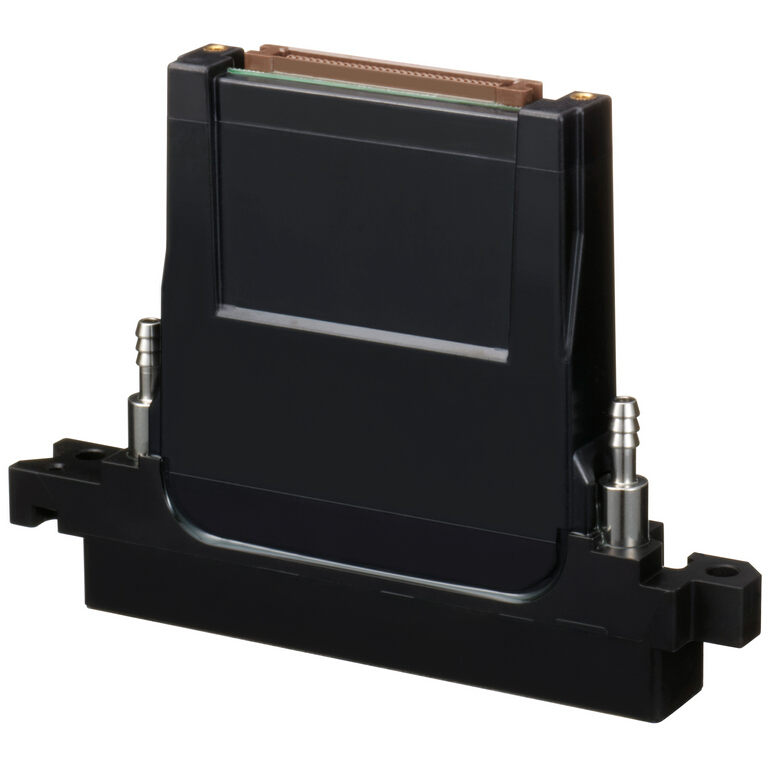

The new inkjet printheads deliver higher resolution, higher accuracy and more enhanced jet characteristics than the existing printheads. Konica Minolta’s independently developed MEMS technologies have enabled the new inkjet printheads compact in size and compatible with a wide range of inks. With the introduction of these new products, Konica Minolta meets the market’s needs for higher performance inkjet printheads and will contribute to further growth of the printer market and the development of new industrial inkjet applications.

Major Features

High-density Nozzle Array Head

Konica Minolta’s independently developed MEMS technologies have enabled 1024 nozzles to be arrayed three-dimensionally in high density. Furthermore, the company’s proprietary robust design*2 has realized both high-resolution and high-accuracy inkjet printheads.

Improved Ink Resistance and Wide Viscosity Correspondency for Every Industrial Ink

Based on Konica Minolta’s long-fostered material technologies and highly heat-resistant design, the new printheads have improved resistance with inks, ranging from low-viscosity inks (aqueous inks) to high-viscosity inks (including UV inks and solvent inks), and compatible with every industrial ink.

Good for Use in Commercial Printing and Label Printing with Requirements for Higher Definition, Along with Printed Electronics (PE)*3

As the new printheads can print with higher resolution than existing products, they have improved applicability to commercial printing and label printing which require higher definition. They can also be used for PE and other applications that need higher jetting accuracy.

Ideal to Design High-resolution and Compact Printers

As the nozzle integration has made the printheads very compact, they can help printer manufacturers design high-resolution and compact printers.

See below for specifications.

Konica Minolta’s Inkjet Development and Production Technologies

Konica Minolta has been on the research and development of industrial inkjet technologies for more than 30 years since the infancy stage of the inkjet industry. While accumulating technological advancement, the company has spearheaded in understanding and meeting the market needs. With its expertise and competitive edges in the development and production for all of the ink, printhead and printer, the three key elements of inkjet printers, Konica Minolta has established robust design technologies to satisfy technical requirements of inks and printers. In addition, the company has developed not only MEMS process technology, which is important and essential to design and manufacture MEMS printheads, and inkjet printhead design technologies but also Robotic Assembling System, a new production technology for mass production.

Industrial inkjet has been rapidly expanding its scope of applications, ranging from commercial and graphic printing to digital textile printing, ceramic printing and PE, among others. For further growth of the market, it has become essential to address technical challenges such as higher resolution, improved image quality, higher speed, enhanced durability and compatibility with a wider variety of inks. With such market and technological backdrop, Konica Minolta has moved to develop the new industrial inkjet printheads.

Going forward, under the brand proposition “Giving Shape to Ideas,” Konica Minolta will develop highly value-added inkjet products based on its proprietary technology, contribute to expansion of industrial-use inkjet technology applications and the market development, and aims to be a company that is vital to society.

*1 MEMS (Micro Electro Mechanical Systems): Technologies to micro-sized mechanical systems on a substrate, such as silicon or glass. Highly advanced fine-processing technologies on micron scale are required.

*2 Engineering design responding to variation in the precision during production process.

*3 Manufacuring of electronic circuits, sensor, elements and other electronic materials with printing technologies.

Source: http://www.theimagingchannel.com/

You’re Welcome to Contact Us!

You can provide opinions and comments on this story!

Or you can send us your own story!

Please contact Doris Huang, Head of News & Editorial, via Doris.Huang@iRecyclingTimes.com

Leave a Comment

Want to join the discussion?Feel free to contribute!