Helping to Make Cartridges Work Better

Helping to Make Cartridges Work Better

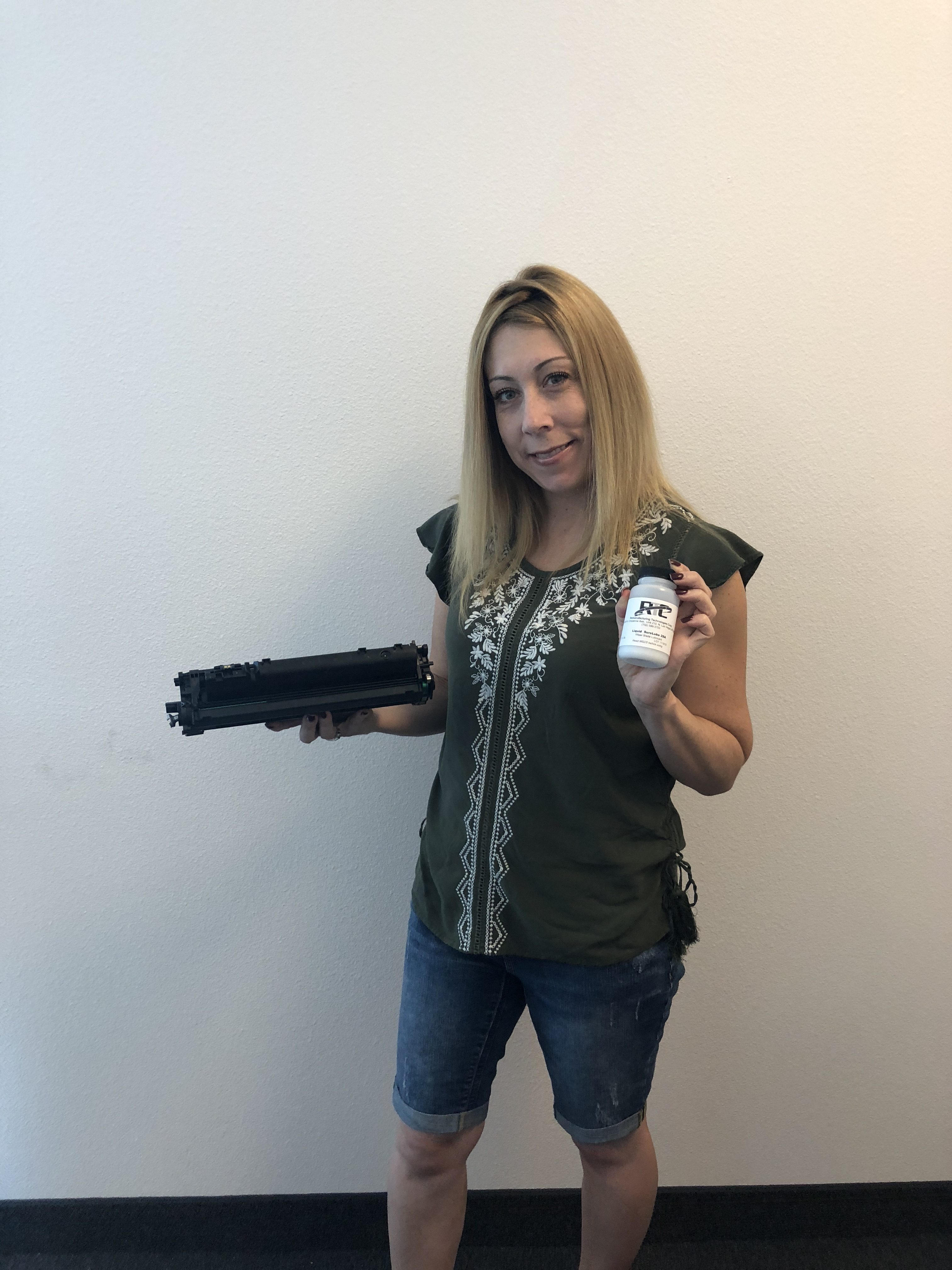

Hear from Katie Bandle, Director of Operations for Remanufacturing Technologies Corp. (RTC), discuss the company over the years. Whose owners have been producing coatings for cartridge remanufacturing and other industries for more than 35 years.

What has made RTC so successful?

We don’t actually make the cartridges—we make the cartridges work better.

We don’t make pilot visors—we just make them fog-resistant so pilots can see better. We don’t make industrial ovens—we make the lights in them shatterproof. Who wants glass in their soufflé?

Lester Cornelius (pictured) started RTC. He used his prowess in ophthalmic coatings to help find solutions to problems in many industries, including cartridge remanufacturing. His coatings are in all the cartridges produced by the industry’s largest remanufacturers. Lester passed away in 2011, but we are keeping his legacy alive by continuing to find solutions to industries’ problems.

Lester Cornelius (pictured) started RTC. He used his prowess in ophthalmic coatings to help find solutions to problems in many industries, including cartridge remanufacturing. His coatings are in all the cartridges produced by the industry’s largest remanufacturers. Lester passed away in 2011, but we are keeping his legacy alive by continuing to find solutions to industries’ problems.

How do you solve problems for cartridge remanufacturers?

Blade flipping is a common, but catastrophic problem for cartridge remanufacturers. Our most popular product, Liquid Surelube 2SA, is a patented, fast-drying coating. When applied to a new or used blade, it virtually eliminates blade flipping. What’s even better, Liquid Surelube also reduces OPC wear—by 2.5 microns per 10,000 pages on average.

This coating also eliminates the need for OPC powder. One unit of our product will coat more than 350 blades reducing the cost to pennies per cartridge. It avoids serious problems while improving the ability for remanufacturers to reuse blades and drums.

Another favorite product for cartridge remanufacturers is Lightning Grease, which is an electrically-conductive grease that enhances charging in cartridges. As opposed to thermally-conductive grease, which is an insulating material and will interfere with charging. Lightning Grease has been proven to effectively eliminate “chatter” in cartridges.

You are the first and only. What has kept customers coming back for the last 35 years?

With nearly a decade with the company, I have devoted myself to customer service. Whether that means being the same friendly voice on the phone or working with our logistic and engineering partners, I am always building relationships. And I’m one of the newest employees!

The folks here are about solving problems. Lester was not just about solving product problems with coatings, he wanted to solve industry problems with individual action. He was the founding chairman of the International Imaging Technology Council. He instilled in us all that our customers’ successes were our successes.

RTC manufactures coatings that require the use of chemicals. Are they safe?

We ship to customers all around the globe. Some of our products include solvents or other materials that are classified as dangerous goods.

Therefore these products require special certification for transport. Cutting through the red tape of customs and proper packaging have become second nature to me, which assures my customers get our products as quickly and safely as possible.

So buyer beware! Anyone that tells you their product is the same, but isn’t classified as hazardous material could be putting your business in jeopardy. They–and you—could be on the hook if a carrier crashes because the product wasn’t properly packaged and transported.

Where are your products manufactured?

All our products are manufactured in the United States, in beautiful Las Vegas, Nevada. I walk the manufacturing floor and make unannounced visits to the warehouse on a regular basis. We take great pride in ensuring the safety of our employees as well as providing a consistent quality product for our customers. Lester wouldn’t have it any other way. And neither will I.

Leave a Comment

Want to join the discussion?Feel free to contribute!