Lower Defect Rates for the Konica Minolta C360i

Lower Defect Rates for the Konica Minolta C360i

“Customers are those who wish us the best and help us the most.”

Once we understand this sentence above, we will surely draw strength from our hearts in the same way loving parents do with their children.

Is it really possible to “love” your customer? For some, possibly many, yes, it is easy because you have fostered a good relationship with them. Even when something goes wrong, the relationship is only strengthened because you have an opportunity to work together to solve the problem.

How about the customer that is difficult? Some are troublesome, demanding, and at times downright rude. Is it possible to “love” them too?

One way we at Sino Print have found to be effective is to provide customers with what they really want: low defect rates on the toners and spare parts we supply. This has become a great tool to develop strong relationships.

In order to meet low defect rates, we do not compromise on cheap raw materials. At the same time, there is a demand for quality products from their customers, so it provides a win-win-win scenario where the end user is happy, and the customer is making good profits from the regular supply. We as the supplier have a growing base of happy customers that also translates into a good bottom line.

I have received requests, after the previous article I wrote, from customers wanting Sino Print to continue sharing information about common defects.

When I analyse customer responses from the poll voting on our Linkedin posts I note the hot-selling Konica Minolta Multifunction Color bizhub C360i/C300i/C250i models are popular with the MPS and rental market sectors.

There are three common quality complaints that are a real headache for our customers: the developer units, the drum units and the primary charge rollers (PCRs).

So, here we go.

The Developer Unit (DV315): this is responsible for transferring the image onto the paper before it goes through the fusing unit (which bakes the image onto the paper).

The main reasons for headaches are as follows:

- Blade: after the copier has worked for a long time, it builds up a lot of wastepaper dust and scraps. This is the main reason for damage to the transfer belt. In this case, you need to replace the blade in a timely manner.

- Poor quality toner powder: it is true that such toners will leave more waste toner in the machine. Adding this to the usual paper dust and scraps can lead to a very big problem with the device.

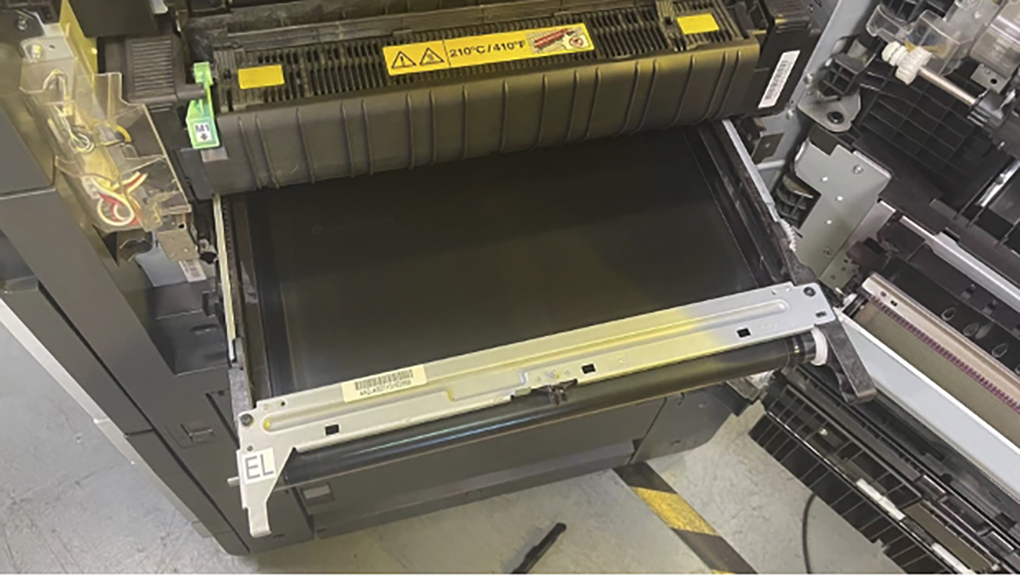

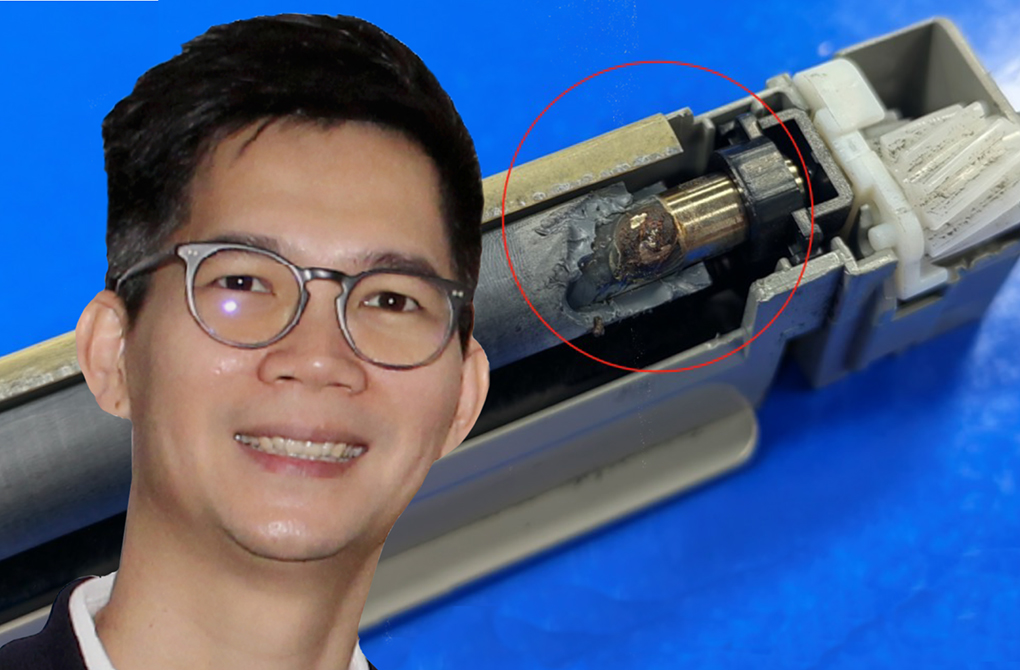

Further, when you print in color, there is not just one toner being dumped in the machine, but four (CMYK). The trouble caused by poor-quality toners as well as normal wear and tear means that the transfer belt needs to be replaced (see Picture 01):

The OPC drum is responsible for receiving the digital code from the device and transferring the image to be printed onto the paper.

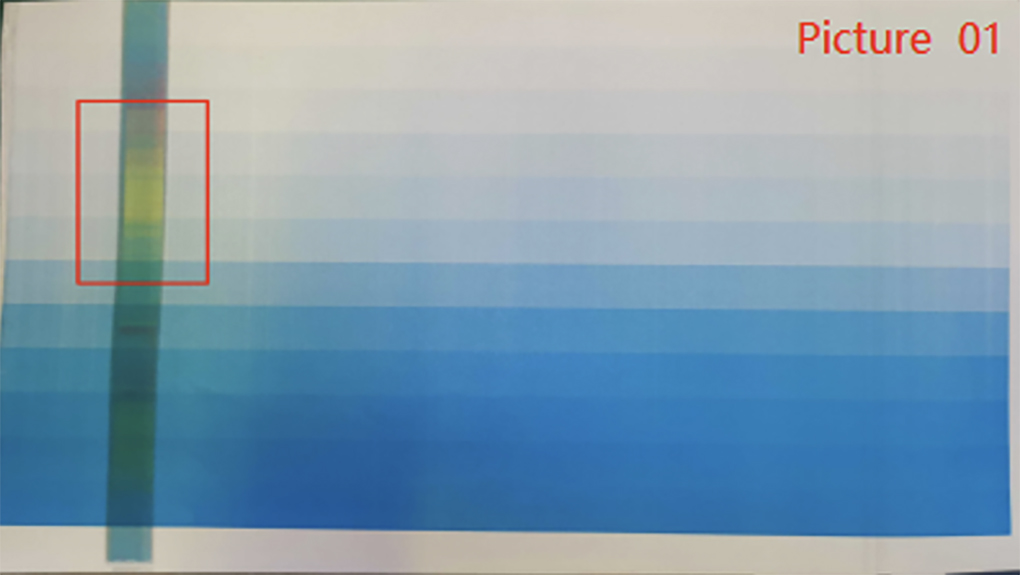

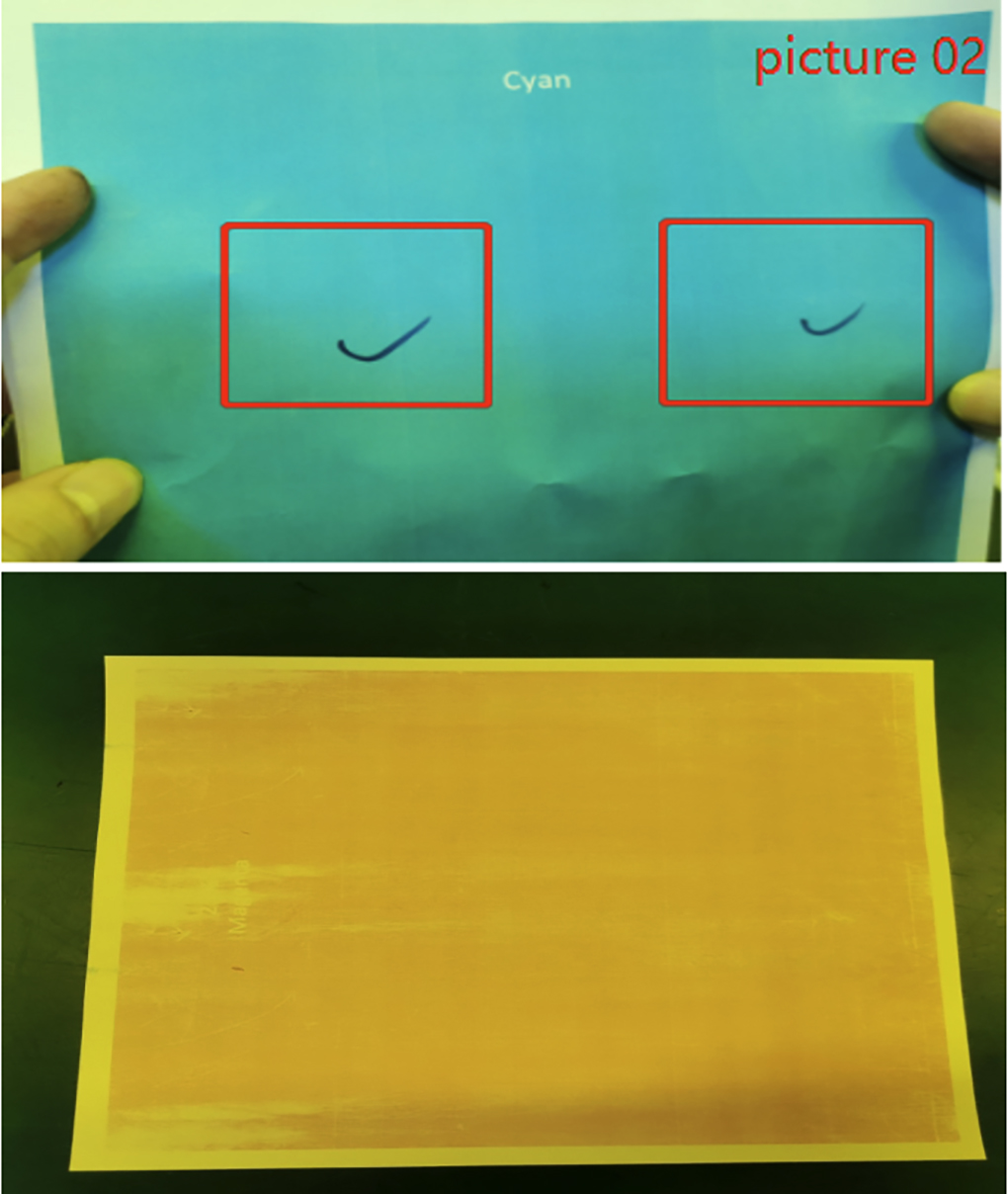

The main reason for the problems here is OPC drum damage. How can you confirm whether the poor-quality prints are caused by the OPC drum or not? You can judge this by examining the printed page. Note, it is different to A4 printers which have three revolutions of the drum for each page, resulting in three similar marks on the page. With copiers, there are only two revolutions of the OPC per page, so the faults will only be seen twice (see picture-02):

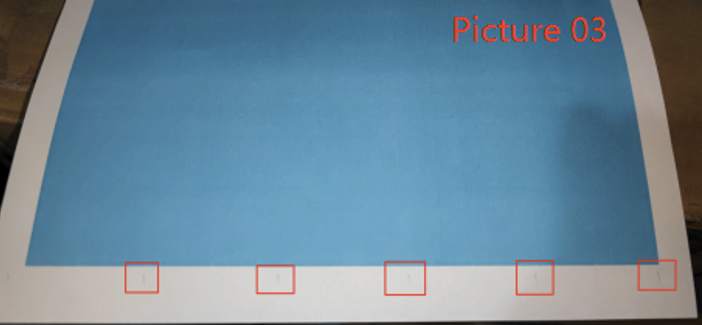

The primary charge roller (PCR) is responsible for erasing the electronic image from the OPC drum ready for a new electronic, digital image to be applied as the drum continues to revolve. Remember the drum revolves twice for each page. As with the OPC drum, it can also leave marks on the page where the roller is worn or damaged. Because the PCR is much smaller and rotates many times, the fault will appear many more times on the page. There is a shorter distance between the faults on the print (see picture 03):

Mr Inamori Kazuo, the founder of Kyocera, once said: “The origin of product manufacturing is the production line, and the origin of sales is the customers.” There will always be problems in life, in business and in the printed pages. The only way to solve the “crime” is to return to the scene where everything went wrong.

If you are sitting at your desk, it doesn’t matter how hard you are working at your computer, you can never solve the problem.

You must go to the scene of the “crime” You must enter the heat of the front line of the battle (and hear the gunfire). You must go together with your customers and enter their hearts to understand their demands and pains.

This is the most important thing about being a successful supplier.

Ben T Chen is the owner of SINO PRINT, a company with 20 years of experience in manufacturing. SINO PRINT is a quality copier imaging supplies provider focussing on Kyocera, Rico, Konica Minolta, Canon, Xerox, Sharp, Utax, Olivetti and Triumph Adler devices for buyers across the globe. Ben’s experience includes marketing, shipping, supply and manufacturing chains.

Email Ben at ben@sp-copier.com

Related:

- Ben T Chen: Lower Defect Rates for the Konica Minolta C360i

- Ben T Chen: Lower Defective Rates Are the Basis for After-service

- Ben T Chen: Customers: those who wish us the best and help us the most

- Ben T Chen: Who are Your Buyers, Who are Your Suppliers, Who are You?

- Ben T Chen: Sourcing Quality Products at the Right Price in China

- Ben T Chen: You Cannot Always Blame the Pandemic

Comment:

Please add your comments below for this article, “Lower Defect Rates for the Konica Minolta C360i.”

Leave a Comment

Want to join the discussion?Feel free to contribute!