Printer Cartridges: New Standards set by Russians

Russians Set New Standards for Printer Cartridges

Since the creation of the first electrographic machine 70 years ago, printing technologies have continued to evolve in a radical or even a revolutionary way. Today, we have a totally different industry compared to what we could have imagined even just a few years ago. Russians set new standards for printer cartridges to help consumers needing help to make the right choice and prevent unscrupulous players.

Since the creation of the first electrographic machine 70 years ago, printing technologies have continued to evolve in a radical or even a revolutionary way. Today, we have a totally different industry compared to what we could have imagined even just a few years ago. Russians set new standards for printer cartridges to help consumers needing help to make the right choice and prevent unscrupulous players.

Direct transfer technologies ruled supreme back then. Today, this technology, within the overall volume of industry’s production, has decreased to one-third of the share it used to have. And it continues to steadily shrink. Practically most office/home printing today is a laser type. Its optimal quality, efficiency and cost established it early as the market leader. The solutions provided by the leading printer manufacturers are the “top of the cream” when it comes to engineering thought—ideal technological masterpieces coupled with a large number of production sites across the world.

However, there is one “however” and it is price. The solutions from any of the OEMs are quality ones, but they are not cheap. The attack on this niche of the market has always been quite foreseeable. The only question has been who will make it, and when.

Russian scientist Tatiana Kashinskaya is featured on the cover of RT ImagingWorld – Business Inform Magazine in Russian

China came along with its price-dumping and defect-ridden products, yet remained in the market. Today, everyone has to reckon with its presence in the market. Manufacturers from this empire have had to improve and adjust to the market needs and this has all taken place right before our eyes. Quality has risen and the range of products being offered has broadened. It was not so long ago that OEMs could speak of Chinese consumables as being of “horrible” quality and “evil” for the equipment in which they were intended. Today, the line between OEM and compatible products has become so thin that only experts, competent in their field, can identify the quality differences.

Let’s not forget there are many service and manufacturing companies still actively engaged in the refilling and remanufacturing of cartridges. Their vision of quality also makes an impact on the general landscape of the market making it all the more difficult for the consumer to make a choice.

During its years in the industry, the Laboratory of Electrography has faced, and still faces, the problem of mutual understanding between the participants of the printing industry. The consumer, who is being attacked from all sides with the streams of marketing and technical information, is quite often incapable of making the choice and even having done so is not protected from receiving products and solutions with quality lower than what was declared by the supplier. In such cases, the consumer usually lacks the competence to defend his/her interests and is forced to suffer economical, reputational and other losses.

Working in the Russian market we understand this market has its own unique and specific requirements based upon our structure, national law requirements and various other factors. At the same time the manufacturers of consumables—including Chinese products—do not always take this into consideration, since they supply products to customers all over the world—not only in Russia. They have customers in the Americas, Australia, Europe, Asia and Africa. Each has their own specific technical standards and buyers’ requirements. These vary strongly from place to place. This includes buying capacity tas well as thinking and understanding about printing quality. There are also other considerations including voltage standards, differences in public technical standards and certification.

Working in the Russian market we understand this market has its own unique and specific requirements based upon our structure, national law requirements and various other factors. At the same time the manufacturers of consumables—including Chinese products—do not always take this into consideration, since they supply products to customers all over the world—not only in Russia. They have customers in the Americas, Australia, Europe, Asia and Africa. Each has their own specific technical standards and buyers’ requirements. These vary strongly from place to place. This includes buying capacity tas well as thinking and understanding about printing quality. There are also other considerations including voltage standards, differences in public technical standards and certification.

Everyone knows that one criterion for evaluating a market’s potential is the presence of niche market needs for replacement products within the “price-quality” category and which products are capable of providing the same quality with lower prices. Unfortunately, in our case, we have a tacit degradation within the market taking place. The customer is offered a lower price for uncontrolled, low quality. What counts as a “bad quality” in Europe and the USA is being sold and purchased in the Russian market. All this takes place independently from the demands of the Russian consumer, who, in turn, has serious difficulty in making the right choices in favor of a product which fits best with his/her understanding of quality.

That is why we have created a set of unified and important requirements in regard to products, quality standards and characteristics which must be strictly adhered and conformed to. The Laboratory of Electrography, which gave a presentation of a new project at the Business-Inform 2019 Expo in Moscow in May, has now launched the standardized test method for evaluating “operative-office printing” (LEM).

The idea of the project is to create an instrument equally comprehensible for all market participants, an instrument that will allow all to impartially judge the product’s quality and usage possibilities. The Laboratory of Electrography has created the educational center and developed learning programs in order to train and prepare profile specialists. The specialists completing the course can become experts in the field of printing quality evaluation.

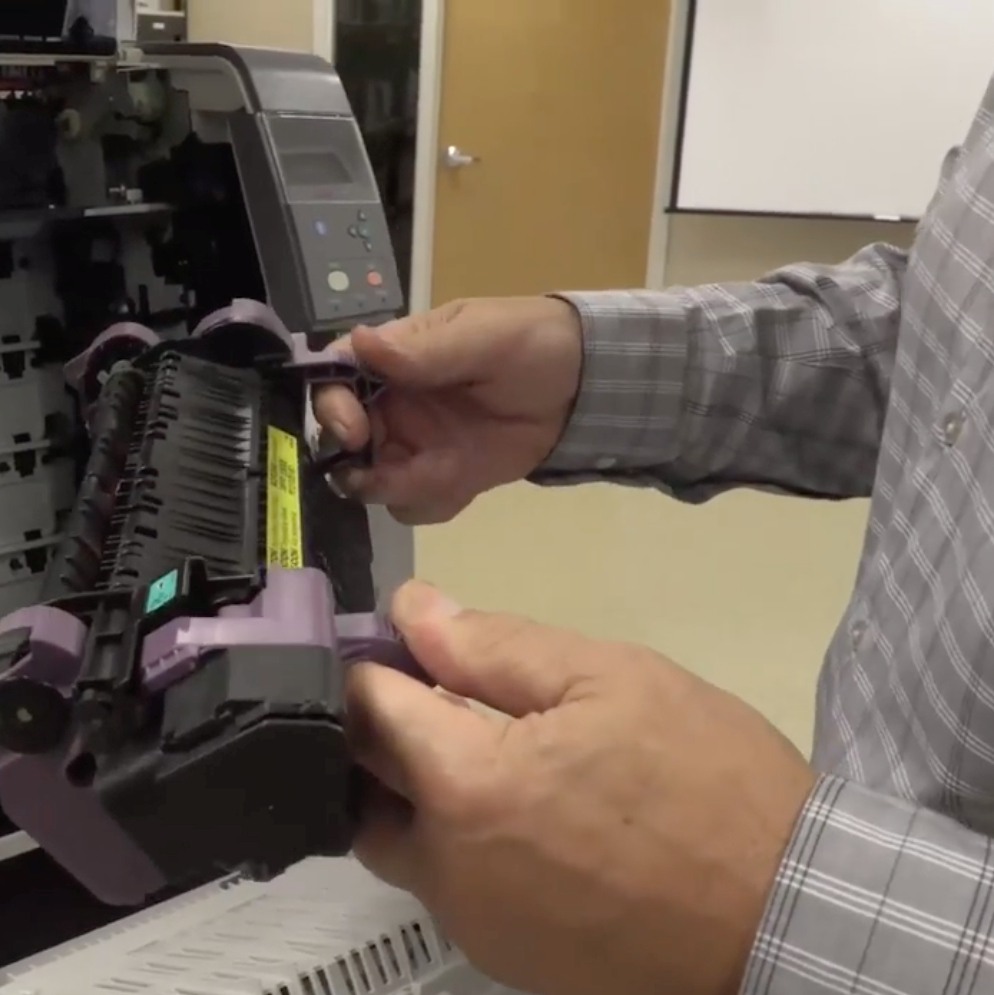

The LEM standardized test method consists of two main parts.

During the first stage, the quality of the print is being evaluated. The evaluation can be requested by anybody interested in the information (manufacturers, suppliers, end-users). The test print evaluation takes place according to the method-related test-objects containing printing elements allowing the control parameters to be measured and a visual study of defects and printing problems is performed.

Parameters for measuring include optical density of the image, background, and adhesion.

As criteria for quality evaluation of the parameters above, average values for optical density of image, background and adhesion—inherent in OEM products—have been chosen.

The print defects within the test method include such parameters as ‘offset’ and ‘wave’ being consequences of electrographic process disruptions denoting unsatisfactory print quality and possible future printing problems.

The problems identified on prints such as satellites, spaces, white spots, heterogeneity, ghosting and bad resolution (according to Burmistrov’s test-object) are considered to be minor defects and demonstrate limitation of printing in terms of graphical objects, micro-printing and bar-code printing, etc.

The method of evaluating the quality of print models is faced by end-users in their work when they send a test-page for printing and try to evaluate the resulting print. The results of such evaluation do not allow to make the right assumptions regarding the yield and performance stability in the printing process.

A good quality performance experience at the beginning of the printing cartridge cycle is not always repeated when that resource nears to the end of its life.

That is why our LEM test method includes the second stage which is directed at studying the quality of printing throughout the whole yield of the consumable or consumables combination being tested.

The evaluation of parameters is being made according to the same criteria as on analogous test objects for identifying the quality of print. Test objects are being printed with 500-1000 pages interval with 5% text coverage according to ISO/IEC 19752.

The study identifies such parameters as printing yield, toner spending for 1,000 pages, the effectiveness of the toner’s transfer to paper and performance stability.

According to the results received the experts produce their opinion and the LEM certificate regarding the quality of the product and possibilities of its usage.

Both stages (parts) of the LEM method, viewed as two separate methods, have undergone long years of trial in various applied manufacturing and scientific projects and showed their justifiability and universality.

We are confident that this type of research and resulting opinions might attract:

- corporative customers, who whom the standards of printing quality represent a tool of defining the professionalism and reliability of their suppliers;

- procurement and sales specialists who are faced every day with the necessity for simple and easy-to-understand criteria for evaluating printing-organizing-products in their field;

- service company engineers for whom it is important to know and understand how their customers will evaluate their work;

- heads of service companies interested in the stability of relationships with their customers and suppliers for their technological solutions;

- IT-technologies specialists wishing to enlarge their competence in the adjusted fields;

- the manufacturers of consumables interested in understandable standard parameters, defining the quality of the product within the boundaries of understanding how the product should look in the eyes of consumers.

We are in the very early steps and stages of the process, but it is already evident, that this way is the only right way for achieving a compromise between the market participants. The knowledge and tools we offer to consumers can help them to make a right choice and prevent unscrupulous players—who think quality is an abstract marketing concept and not a law of manufacturing—from entering the market. We are hoping for understanding and count on support from everyone interested in quality printing, our industry’s development and profitability within the Russian market.

Meet the author in Zhuhai on October 18, 2019

Russian scientist and process chemist, Tatiana Kashinskaya will speak to the global printing consumables interested in the Russian market to explain how the new policies may impact them wanting to sell printing consumables into this lucrative market.

Russian scientist and process chemist, Tatiana Kashinskaya will speak to the global printing consumables interested in the Russian market to explain how the new policies may impact them wanting to sell printing consumables into this lucrative market.

She has extensive experience in the development and manufacturing of toners and is author of more than 30 inventions and patents. Since 1998, she has been working in the compatible supplies industry, researching the quality of toners and cartridges for laser printing. She is the developer of Russian methods for evaluating the quality of prints and cartridges (LEM).

Position: General Director, Laboratory of Electrography Ltd. (Russia), Head of Expert Council on Evaluating the Product Quality in AQCMS (Russian Association of Quality Consumables Manufacturers and Suppliers)

If you are more interested about Russians printer cartridges, more information here.

Leave a Comment

Want to join the discussion?Feel free to contribute!