MIT Develops Ink to Change Color of 3D Objects

![]()

Originally Sourced from CNNtech

MIT has released details of a method called ‘ColorFab’ for recoloring 3D printed objects after they have been printed.

This came about in an effort aiming to reduce waste with a method combines software, hardware and special 3D ink.

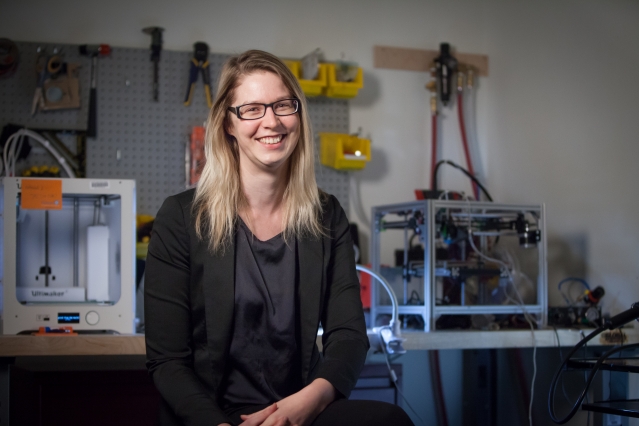

“Manufacturers and designers spend significant amounts of time, energy and money re-printing designs when they don’t come out exactly right the first time,” Stefanie Mueller, co-author of the paper and professor at MIT’s Computer Science and Artificial Intelligence Lab said. “This technology could help minimize the amount of waste that is produced from updating products.”

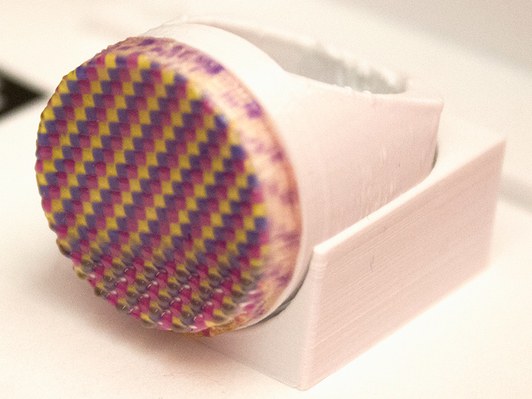

The ColorFab interface lets users upload a 3D model, choose a color and then print by using a specialized 3D printable ink that changes color when it’s exposed to UV light.

The ink includes a base dye, a “photoinitiator” and “light adaptable” dyes. The latter brings out the color in the base dye, while the photoinitiator hardens the base dye during printing.

Researchers say that the color can be changed on an object within 20 minutes, and hope that time will lessen when advancements are made in the future.

Right now, the research is focused on common 3D printed materials such as plastic, but researchers hope it could ultimately be used on a wide variety of other items, such as metals for jewelry.

“Accessories, such as earrings, bracelets, necklaces, and smart watches tend to be worn on an everyday basis, making it difficult to pick a color that matches all outfits,” the paper says. “With ColorFab, such accessories can be recolored depending on what the user is wearing.”

“I’m hopeful that in the future this sort of system could help encourage consumers to be more mindful about their purchases and maybe buy just one of something instead of buying it in every single color.” Mueller said.

Leave a Comment

Want to join the discussion?Feel free to contribute!