ASTM Adds New Metal 3D Printing Standards

![]() Original published at 3D Printing.

Original published at 3D Printing.

ASTM Adds New Metal 3D Printing Standards, Additive Manufacturing Center of Excellence Partner

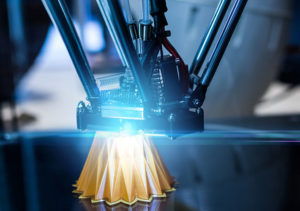

According to 3D Printing, a new ASTM International standard is geared towards the increasing use of metal additive manufacturing for medical, aerospace, and other parts. The new standard, soon to be published as F3303, addresses ways to qualify machines and processes that help build parts using laser or electron beam powder bed fusion. It also outlines the related steps needed to configure and control digital data. The standard was developed by ASTM International’s subcommittee on materials and processes, which is part of a larger committee on additive manufacturing technologies.

Another new standard, soon to be published as F3318, has been developed to support the 3D printing of aluminum alloy parts on laser powder bed fusion machines.

Standards may seem like a dry subject area, but they are a necessity in the industries in which metal additive manufacturing is being used. If you’re flying in an airplane that contains critical 3D printed parts, you’re going to want to know that those parts have been built according to standards set forth by a knowledgeable organization; likewise, if you’re a hospital ordering 3D printed surgical tools, you’ll want to be assured that each of those tools has been manufactured using the same precise methods.

Standards may seem like a dry subject area, but they are a necessity in the industries in which metal additive manufacturing is being used. If you’re flying in an airplane that contains critical 3D printed parts, you’re going to want to know that those parts have been built according to standards set forth by a knowledgeable organization; likewise, if you’re a hospital ordering 3D printed surgical tools, you’ll want to be assured that each of those tools has been manufactured using the same precise methods.

Metal additive manufacturing is a tricky process, and everything from the quality of the metal powder to the means of removing supports is instrumental in creating a part that functions exactly the way it is intended to function, without risk of failure. A lot can go wrong in the metal additive manufacturing process, so quality assurance and testing standards are equally important in ensuring that every part has been thoroughly assessed before being put into use.

Recently, ASTM International announced its new partners – EWI, Auburn University, and NASA – for an Additive Manufacturing Center of Excellence, which, according to ASTM President Katherine Morgan, will “build a strong foundation for the future of additive manufacturing…(and) will help fill industry gaps and accelerate innovation.” The selected organizations and their partners will work together to form a hub that advances technical standards, related research and development, education and training, and more.

Leave a Comment

Want to join the discussion?Feel free to contribute!