EXCLUSIVE: New Cartridge World Shareholder Provides Non-Infringing Drum Recoating Solution

SGT’s Richard Yu believes remanufacturing is the best answer

Doris Huang, Head of News and Editorial at RT Media

Recoat to Avoid Infringement

“What—Again?” The cry broke the silence in the printer cartridge aftermarket camp last January when Canon complained the industry was yet again infringing its patents. This time, Canon claimed the coupling mechanism used to connect a toner cartridge to the drive motor inside the printer—often called the dongle gear—was the issue. It would seem Canon was exercising its patent rights over combined patents it holds on the OPC drum assembly—or OPC System—which means remanufacturers infringe their patents by simply disassembling the tough reusable gear from the worn out drum.

Consequently, the entire remanufacturing industry was at threat and “all at sea”, not knowing what to do to avoid infringement.

Coating worn out OPC drums has been around for more than two decades and is a permissible repair and refurbishment solution for remanufacturers. But it was unreliable.

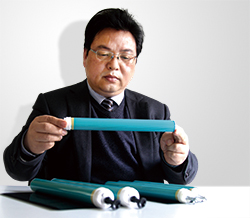

Dr. Richard Yu, Chairman of Suzhou GoldenGreen Technologies, believes his “new” recoating technology is the solution the aftermarket has been waiting for.

Dr. Yu spent almost a year, with his R&D team, redeveloping recoating technologies to overcome the obstacles of disassembling and reassembling the OPC System. Adopting physical and chemical methods, the process allows a used OEM drum to be cleaned and recoated so that worn OPC parts are replaced with an OEM substrate, while using the existing gears and rotating arm. Thereby the process becomes permissible repair on the OEM-used drum without the need to change the key parts of the OPC System that risked infringing the OEM patent.

In response to those who tried recoating 20 years ago, and suspicious of the “new” technology, Dr. Yu says, “The conventional recoating technology simply polished the surface and added a protective layer to extend the life of the drum.” He added, “The OPC products nowadays differ largely from what they used to be. OEMs improved printer performance with faster print speeds (30-40 pages/ min), higher page yield (sometimes more than 6,000 pages), and better printing quality. The coating thickness of drums used to be 25 microns but now it’s about 10~12 microns. Needless to say, an OPC drum is used in an abrasive environment where its surface is worn down by toner, wiper blades, and paper surface. In addition, the electroconductive toner sometimes would puncture through the coating, creating flecks, making it more difficult for cleaning. All these add damage to the life expectancy of an OPC drum, which is seriously depleted after its first life cycle. Hence, conventional polishing and recoating methods won’t work at all.”

Dr. Yu added, “We’ve come up with different methods to deal with different circumstances. We even modified our production line to cater for the need. However, to evaluate the success of the technology, we also need to look at its success rate, otherwise the enormous investment is in vain. To achieve a high success, or pass rating, was also a big challenge for us. However, after more than a year’s research and development, we consistently hit more than a 90 percent pass rate.”

Dr. Yu declined to reveal further details of his “new”, unique recoating technology, but he is confident it does not infringe the OEM patents and their own patents of the recoating technology are under the registration process. “The aftermarket industry sometimes should go back to the essence of remanufacturing and use remanufacturing technology to produce quality products customers like.”

Still Full of Hope

Founded in 2002, Chinese-based SGT is now among the world’s largest OPC manufacturers, producing more than 50 million new OPC drums every year. Over 90% of SGT’s 50 million OPCs are sold to the aftermarket and less than 10% the OEMs.

With more than 20 years’ R&D experience in functional nano-materials, photoelectric materials and products, organic photoconductor formulation and production, Dr. Yu said he was destined to devote himself to the OPC industry. He dedicated his undergraduate, graduate and doctoral study programs to studying the core of OPC drum technology. Following the completion of his doctoral program, he worked for Mitsubishi Chemical in Singapore and quickly moved up the career ladder to become its principal engineer. Later, he returned to his hometown—Suzhou, China—to start his own business. Dr. Yu and his partners saw opportunities in the emerging and immature printing consumables market. They believed, that despite the prevailing economy, whether good or bad, consumers and the development of digital and internet technologies would continue to drive print demand.

Dr. Yu continues to be optimistic, “Generally, the printing consumables market continues to grow, especially in China, through a mature industry chain, cost advantage and increasing quality.”

OEMs continue to look for a cooperation with SGT. They test and evaluate its products. Dr. Yu keeps the faith that SGT will grow a higher revenue share from the OEMs as they call for high quality products.

Challenges Are Welcomed

In a very competitive market, where prices have declined significantly, SGT has emerged as the industry’s No.2 largest OPC manufacturer around the world.

Dr. Yu says, “The price pressure comes from both domestic and international markets. Customers demand quality products at a reasonable price. Quality is something we will not sacrifice. In fact we continue to increase it. While our price is definitely not the lowest in China we can offer the best cost performance.”

Dr. Yu welcomes competition as it accelerates innovation. He asserts, the key to winning the pricing war is to sell high volume, high quality, low price products because the profit margin is small. This requires innovations in technology, production, material, product performance and company management in order to reduce costs.

As the industry evolves, there are also more and more mergers and acquisitions. Yu said it is an inevitable trend as the industry matures. A lot of low-level companies will be sifted out, and the mainstream companies will pilot the industry, offering better products for consumers. It’s the law of nature in all industries.

OPC makers also face challenges from the OEMs. Dr. Yu discloses, “It’s unlikely for OEMs to restrict the aftermarket via material or formulation now. In the future, they are more likely to restrain aftermarket players via structure-related patents, especially gears or coupling mechanisms.” Yu thinks OEMs have every reason to protect their intellectual property rights as they’ve invested heavily into research and development. He applauds the OEMs for their innovation and for raising the bar but believes every challenge is surmountable.

Into to the Future

When asked if SGT will enter other areas, such as finished products, Dr Yu responds, saying the company will continue to focus on its core business—OPC drum, as the market is still rapidly growing. However, he added, “If an opportunity arises, we’ll cooperate more closely with upstream and downstream companies to expand our business.” Many experts believe the future of the printing consumables market is shifting to China. Yu agrees, “Many foreign counterparts may feel threatened by this. However, at SGT, we have a collaborative attitude. We’re very familiar with the Chinese market and have quality products. Our foreign counterparts, on the other hand, are very familiar with their markets and have very good sales channels and brands. I think we should cooperate with each other to better utilize our strengths and provide better products/services to our customers.”

In the past 10 years, SGT has invested mainly in laser, but for the future, it will focus more on copier products. It is now building an industrial plant, expected to completion in 3 years. Dr. Yu predicts the annual manufacturing capacity of OPC drums will be over 100 million by that time. For him, the future is very bright.

Related Links:

EXCLUSIVE NEWS: SGT Becomes a Shareholder of Cartridge World

EXCLUSIVE: Cartridge World Letter Sent to 1200 Masters and Franchisees

EXCLUSIVE: Why Cartridge World Thinks the Aftermarket DOES Have a Future!

Leave a Comment

Want to join the discussion?Feel free to contribute!