3D Printed Concrete Molds Reconstruct Ancient Building

![]() Originally published at 3ders.org.

Originally published at 3ders.org.

EDG creates customizable 3D printed concrete molds to restore historic architecture

In the past decade, the relationship between technology and craft has seen a significant reversal. Usually 3D printing was used to manufacture small objects, figurines and prototypes, it is now being used to construct affordable housing in the construction industry. Artists and artisans across creative fields are embracing digital tools as the new medium for human expression.

According to 3ders.org, the New York architecture and engineering firm EDG has come up with a cost-effective way to bridge technology and craft: Modern Ornamental: a new form of digital sculpture. The key lies in 3D printing.

In developing modern ornamental, laser 3D scanning software, rendering software (like 3DSMax and Rhino) and algorithmic modeling programs allow the company to recreate virtually anything with ease. EDG then selected the right materials and 3D printing technology to make plastic molds; these would be used to produce copies of architectural ornamentation. The team began prototyping with a small MakerBot Replicator Z18.

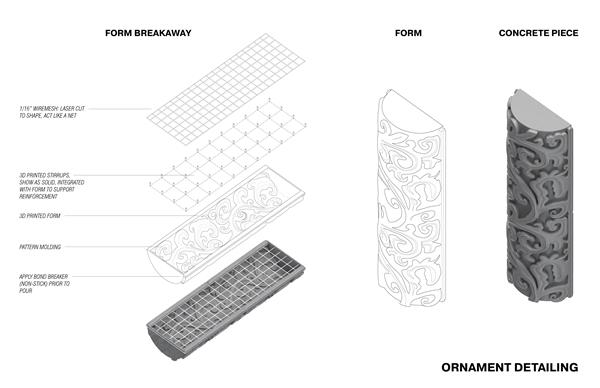

“We focused on hollow form plastic molds for economy—to be filled with standard and colored concrete. Through exhaustive experimentation, we found the perfect balance of material cost, efficiency and strength, ensuring that the molds can be easily reproduced.” says the company.

The 3D-printed plastic mold is inlaid with a laser cut wire mesh to provide reinforcement. The final prototypes were manufactured by VoxelJet using their VoxelJet VX1000 3D printer for the casting molds and were fabricated in-house with Sika concrete.

When on site, these ornaments can reportedly be produced in as little as a day. Additionally, with stored digital catalogue of parts, architects can easily reprint a mold. “Should an element ever need repair or replacement, they could simply be removed from the building, and a new one could be reprinted and recast on-site, the same day.”

The firm was inspired by the pending demolition of 574 Fifth Avenue, a 1940 building with intricate ornamentation which was being torn down because the cost of restoration was too steep. As put by EDG, “Facade ornamentation in the classical style remains impossible to produce by current means. Architectural hand sculpting would be an exorbitant luxury if not also a lost art, laser cutting remains prohibitively expensive, and precast concrete is creatively limiting—as its affordability is derived from the repetition of basic forms. To that end, architects and developers turn increasingly to the restoration of existing treasures, which are in limited and often neglected supply.”

With their method of construction, ornamentation can be designed and incorporated into the facade without exceeding the budget. “This project began with the simple goal of finding a way to salvage and restore many of the deteriorating architectural treasures in New York City, and around the world,” says John Meyer, Founding and Managing Partner of EDG. “The innate beauty and rich history of these gems were vanishing as the cost of their repair became progressively prohibitive. Recognizing the tragedy these losses, which, like Penn Station, often isn’t fully realized until after the fact, we set about creating a cost effective method of reconstruction and repair. Having achieved that, we also quickly realized that the ease and accessibility of this method of construction held the potential for a truly seismic shift in the creation of building facades. Drawing inspiration from classic styles, we transformed those details into something modern and fresh.”

This process will not only usher in the forgotten craft of the “hand” into the modern age, but also democratize the process of design, allowing practitioners from divergent fields to execute what was previously unimaginable.

EDG is building a customized 3D printer suited for their future projects, including a multi-family project in Greenpoint, Brooklyn.

Leave a Comment

Want to join the discussion?Feel free to contribute!