G&G Penguin Lifts the Curtain on Component Specs

G&G Penguin Lifts the Curtain on Component Specs

G&G Penguin Lifts the Curtain on Component Specs

Researchers at the MIT Sloan School of Management have revealed consumers may be willing to pay up to 10% more for products from companies that provide greater transparency if they are better informed about where and how the products they purchase are being made.

According to G&G, the Ninestar company always showcases its raw materials thoroughly and transparently as a matter of priority. It understands its customers’ health needs and their wishes to actively contribute to reducing CO2 emissions.

In order to demystify the kinds of raw materials that are selected by G&G, to make its premium G&G Penguin cartridges, it has publicly released the following information:

Premium G&G Toner Penguin Cartridges

Premium G&G Toner Penguin Cartridges

- Plastic Components: The plastic components enable a toner cartridge to be shaped perfectly and let the cartridge perform excellent compatibility.

- High-precision plastic components, perfectly compatible with the printer.

- Organic Photoconductor Drum: The OPC drum’s important job is to receive the image to print from a laser inside the printer and to transfer the image to paper.

- Aluminum-made OPC with triple coating

- Coating thickness 17±0um

- Wear-resistant and durable

- Toner Powder: It’s a powder mixture used in laser printers and photocopiers to form the printed text and images on paper, which is the main consumable of the cartridge.

- Polyester resin toner, extra high blackness, firm fixing, stunning print results

- Magnetic Roller: The magnetic roller plays an important part in carrying toner, using magnetic fields to attract the toner to the surface of the OPC.

- Innovative true black MR technology

- Long-lasting high blackness

- Primary Charge Roller: Its main function is to charge the OPC to adsorb toner evenly on the drum core, and to eliminate the residual potential on the drum core.

- Rubber-made

- Ozone reduced

- Charging evenly without noise

Premium G&G Inkjet Penguin Cartridges

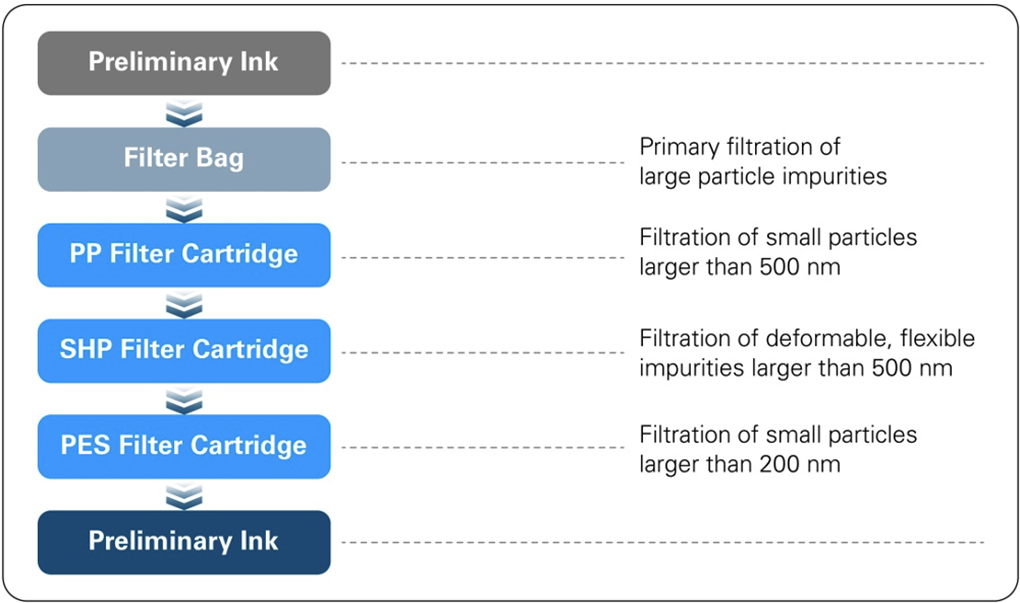

- Anti-Clogging Technology, Smoother Print Experience: G&G premium ink is exclusively filtered through a four-layer micro-nano filtration process, ensuring smooth printing and greatly reducing print head clogging.

- Self-developed High-end Ink Formula:

- Wide gamut

- Crisp and sharp text

- Vibrant color, true-to-life image

- Waterproof, light-resistant and non-fading

- Patented Bottle Design, Easy Refilling:

- Easy refill, zero leakage

- Patented design,

- Stop refilling once the tank is full

However, all of these high-quality components are not sufficient to produce a premium G&G Penguin Cartridge. As a leader in the aftermarket, G&G also possesses cutting-edge automated machines to supply batch-to-batch, consistent quality cartridges.

The whole process is important to ensure every G&G cartridge is safe and friendly to the environment, and complies with the ROHS, and REACH regulations.

G&G is always committed to producing reliable and affordable first-rate consumables for its 200 million consumers in over 170 countries. G&G will continue to fulfill its social responsibility to provide manufacturing process visibility while offering the best-in-class and unexpected service for its partners and customers.

Related:

- Ninestar G&G Pleased with US Customs Ruling

- Ninestar Shortlisted for Print Award

- Scott Odom to Spearhead Sales for Ninestar in Germany

- Ninestar Opens its German Office

- Ninestar Establishes New Warehouse in the UK

Comment:

Please add your comments below about this news story, “G&G Penguin Lifts the Curtain on Component Specs.”

Leave a Comment

Want to join the discussion?Feel free to contribute!