Resilient and Differentiated Lessons I’ve Learned from 25 Years of Supply Chain Innovation

For most of us, supply chains are invisible. And yet they are the backbone of global commerce. They determine whether products arrive on time, whether quality is upheld, and whether businesses can deliver on their promises.

I was impressed with renowned economist Milton Friedman, who eloquently explained how thousands of individuals across continents work to produce something as simple as a pencil. Yes. The humble pencil you purchase at your local stationery store. The wood casing may come from Eastern Red Cedar in the U.S.A. The graphite core is sourced mainly from China, Canada, Brazil, or Madagascar. The eraser is typically made from vulcanized rubber and pumice in Malaysia. The little metal band that holds the eraser is made from aluminium, from Europe, Canada, or Australia. Finally, the paint coating is produced in China, Germany, or the U.S.A. They all come together as a result of finely tuned global supply networks.

I was impressed with renowned economist Milton Friedman, who eloquently explained how thousands of individuals across continents work to produce something as simple as a pencil. Yes. The humble pencil you purchase at your local stationery store. The wood casing may come from Eastern Red Cedar in the U.S.A. The graphite core is sourced mainly from China, Canada, Brazil, or Madagascar. The eraser is typically made from vulcanized rubber and pumice in Malaysia. The little metal band that holds the eraser is made from aluminium, from Europe, Canada, or Australia. Finally, the paint coating is produced in China, Germany, or the U.S.A. They all come together as a result of finely tuned global supply networks.

In today’s world, however, supply chains face increasing scrutiny. From businesses, consumers, and also from governments. You see it in the media.

Disruption has become a key strategic tool. Policies, tariffs, and regulatory shifts are now used to influence trade flows. There is an attempt to protect national interests or change the playing field in regional markets.

In the meantime, your business, and mine, is attempting to meet customer demands. We try to deliver differentiated products that inspire confidence. Navigating this tension requires more than resilience. It requires vision.

Disruption Is Not New

While governments may increasingly use disruption as a geopolitical lever, disruption itself is not new to our industry. Let’s face it, for more than 40 years, the aftermarket printing supplies sector has been a disruptive force in its own right. We have challenged the status quo.

And yet, I like to think the aftermarket has provided choice for consumers. We have provided them with affordability and innovation. They are not dependent on OEM products at premium price points. By doing so, we have kept the OEMs in check by providing real competition. And consumers have benefitted from that.

I have never seen disruption as undermining. Yes, it’s challenging. However, I see it as a strategy for “improving.” Improving designs to respect intellectual property. Improving performance through higher yields and smarter solutions. Improving the market itself by ensuring end-users have real alternatives.

We need to source and test all the raw materials we use in designing and making our products. Hopefully, it is as seamless as the pencil. You simply end up with a product you can trust to deliver a better printing experience.

The Rise of China as a Technological Powerhouse

Another major source of tension I have experienced is China’s rise across multiple technological fronts. Think about how China has become a global leader in electric vehicles (EVs), robotics and automation, high-speed rail, rare-Earth resources and processing and becoming the “World’s Factory.” All of this has relied on strong, reliable supply chains. We, too, have developed our own automated production lines and technologies, along with trusted supply chain partners, to deliver products that can be first-to-market and/or better than the original.

For many regional markets, this rise challenges the status quo. It creates new tensions, especially in industries that depend on secure, consistent, and fair access to resources and products. Yet, our partners, along with those willing to collaborate, continue to tell me it creates enormous opportunities to build stronger, smarter, and more sustainable business opportunities.

Building Resilience into Supply Chains

Resilience is the ability to withstand shocks and adapt to uncertainty. Over the past 25 years, I have learned that resilience cannot be left to chance. It must be designed into the supply chain.

Resilience is the ability to withstand shocks and adapt to uncertainty. Over the past 25 years, I have learned that resilience cannot be left to chance. It must be designed into the supply chain.

That means we have to diversify our sources to reduce dependency on any single supplier or region. It means investing in technology that provides visibility and agility. —from predictive analytics to real-time monitoring of production and logistics. Most importantly, resilience is about relationships. Long-term partnerships with suppliers who share our values—quality, service, and innovation—create networks that can weather disruption.

Resilience is not about avoiding challenges. It is about facing them with confidence.

Differentiation: The End Goal

A resilient supply chain is only half the story. What truly matters is what it delivers. In a crowded marketplace, differentiation is everything. Customers will always ask you: Why should I choose you?

That question can be answered where innovation is happening. Differentiation means higher page yields, smarter cartridge designs, environmentally friendly solutions, and reliability that matches or exceeds expectations. It means products that are not only price-competitive but also value-driven.

And this is only possible when we have supply chains that we can trust. Differentiation is only made possible when these supply chain partners also care about precision, quality, and service as much as we do.

In my view, we ought not just move products from the factory to the customer. We should be moving innovation into the hands of people who need it most.

Looking Forward

As global supply chains continue to face pressures from geopolitical shifts, technological advancements, and environmental responsibility, two things remain constant: the need for resilience and the need for differentiation.

If you have good supply chain partnerships, you can deliver both. AT the same time, as an industry, we need to learn, adapt, and innovate. We should make sure that every cartridge, every product, and every solution reflects such values.

Those companies that will thrive are those that not only withstand change but turn it into an opportunity. This is not just a business strategy.It is essential. It’s what can and will shape the future of imaging supplies worldwide.

*This article has been republished from Eric’s LinkedIn post with permission and editorial adjustments.

About the Author

About the Author

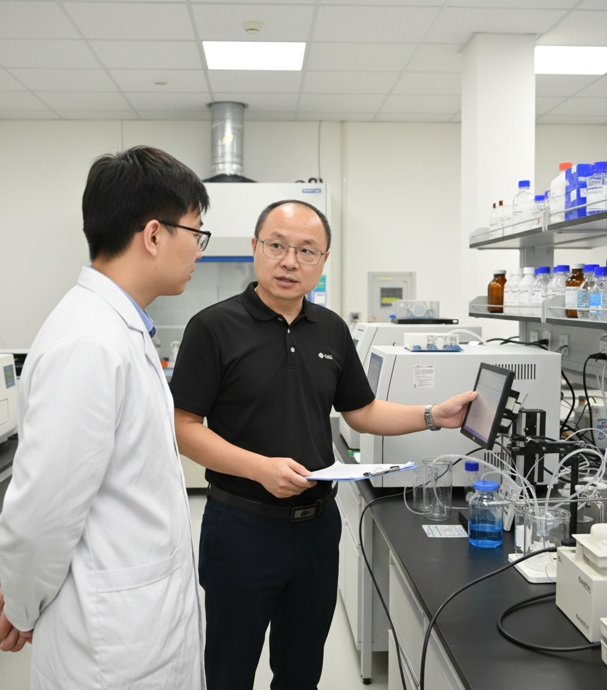

Eric Zhang is the Chief Executive Officer of Ninestar Image Tech and its G&G brand and is recognised as a global leader for innovation, sustainability, and respect for intellectual property in the printing supplies industry. With two decades of experience, Eric has played a pivotal role in shaping G&G’s international strategy and building trusted partnerships across markets. He is passionate about supply chain resilience, technology-driven innovation, and creating sustainable solutions that deliver real value to customers worldwide.

Connect with Eric on LinkedIn: linkedin.com/in/eric-zhang

Related:

- Supply Chains and Market Integration – what are they and how do they work?\

- Resilient and Differentiated Lessons I’ve Learned from 25 Years of Supply Chain Innovation

Comment:

Please leave your comments below for the story “Resilient and Differentiated Lessons I’ve Learned from 25 Years of Supply Chain Innovation.“

Leave a Comment

Want to join the discussion?Feel free to contribute!