New design thinking and re-skilling for a future-ready manufacturing sector

Author: Rob Mesaros, Vice-President of 3D Printing & Digital Manufacturing, Asia-Pacific & Japan, HP Inc

The 4th Industrial Revolution has arrived, ushering in unprecedented change and significant opportunities. The digital technologies on which it is based are increasingly faster, cheaper and more affordable, driving tangible results. Artificial intelligence (AI), machine learning, generative design and big data are accelerating sector growth, while 3D printing is upending the manufacturing sector.

The 4th Industrial Revolution has arrived, ushering in unprecedented change and significant opportunities. The digital technologies on which it is based are increasingly faster, cheaper and more affordable, driving tangible results. Artificial intelligence (AI), machine learning, generative design and big data are accelerating sector growth, while 3D printing is upending the manufacturing sector.

The impact of this digital transformation will be profound; but it will not just be driven by technology. Industry 4.0 also requires new skills and new ways of thinking and working.

For many, this change may seem like a feat. It requires new investments, organizational change and employee upskilling. But keeping pace with Industry 4.0 is a necessity in growing customer relationships and attracting new business.

Shifting mindsets to unlock new possibilities

Take 3D printing as an example. 3D printing technologies allow manufacturers to add and bond layers of material to form a fully-functional part, versus creating injection mold tools. This shift has tremendous impact on the manufacturing process and what it can deliver.

3D printing drives efficiencies – shortening design cycles, lowering overall production costs, and shortening the distance between production and delivery.

It has more nuanced impact as well, changing the ways designers and manufacturers work, the technologies they use, and the training they need.

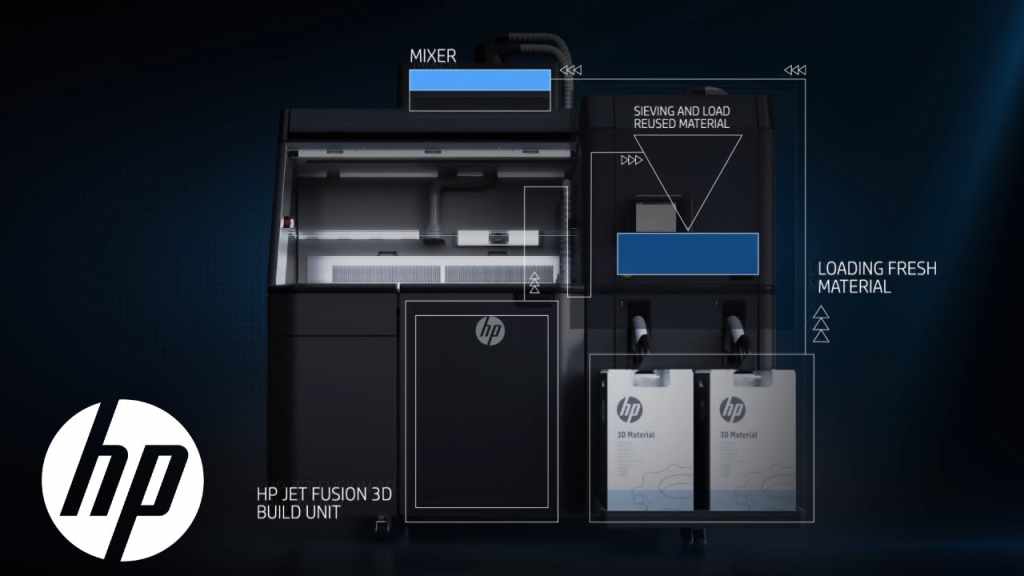

HP Jet Fusion 3D Printing Solution. Image via Stratasys.

First, 3D printing gives designers and engineers a new level of freedom to design and produce their creative ideas. Without the limitations of injection molding, designers no longer need to consider draft angles or seams – even for mass production. To put it simply, they must “un-learn” the constraints of traditional manufacturing, as they are no longer relevant.

Secondly, it requires designers and engineers to more closely collaborate at every stage of the process. Traditional manufacturing flows linearly, with a product starting in design and then shifting to the engineers for prototyping and testing. Once it is signed off, the injection mold is built, and production is started. Designers and engineers have limited interaction. This means that functional aspects, like materiality, structural integrity, and durability of design, are only taken into consideration in the latter half of the development cycle.

The 3D printing ecosystem encourages a more integrated process. As a result, designers must consider how a part will be manufactured from the start of the design cycle. Engineers must also be involved at an earlier stage as new CAD technologies allow functional considerations to be introduced during visualization.

Leveraging new digital technologies

3D printing also creates the opportunity for designers and manufacturers to incorporate new technology into their day-to-day work. Generative design and machine learning are two key innovations driving this change.

As digital manufacturing becomes more ubiquitous, CAD technologies are evolving as well. Today’s CAD software can be paired with virtual reality (VR) or augmented reality (AR) technologies, allowing designers to superimpose any computer-generated imagery onto a real-world setting.

CAD software is becoming even more intuitive, some even created for non-programmers. This is democratizing the field and enabling anyone with design creativity to start their journey towards becoming a manufacturer.

Automated generative design software enables designers to very quickly look at several design permutations of a part, generated from data parameters such as material choice, production methods, and cost constraints. According to Autodesk, the AI system applies generative design principles to generate high-performing design alternatives from a single design.

This is a massive boon as designers can review thousands of AI-generated design options and choose the one that meets their most important criteria. As raw three-dimensional design files are linked directly to 3D printers, this facilitates rapid prototyping with precise amounts of material to avoid wastage.

What companies can do to prepare their employees

With so many new tools available, the right working environment and employee support system is a crucial step in transitioning to digital manufacturing.

It starts with access to technology to encourage experimentation, as engineers who have been trained in the injection molding process will find it challenging to re-skill. The ability to experiment with new tools and experience their capabilities and limitations, will help encourage new ways of thinking.

As engineers are introduced to 3D printing technologies, ongoing training will be necessary. At HP, 30 percent of Indigo printer engineers have undergone Design for Additive Manufacturing (DFAM) training. Several tertiary institutions, from MIT to Nanyang Technological University, have introduced both online and in-class short courses to equip mid-career engineers with the fundamentals, applications and business implications of adopting 3D printing.

HP also helps our customers in this transition. We start with a production line walk-through to better understand our customers’ needs and the ways in which they currently manufacture. As we look at different components along the production line, we can get a sense of each part’s application and criteria. Through this process, we can identify the “low-hanging fruit” – parts that can easily be 3D-printed with minimal cost or impact on existing production cycles. This is where we can partner with companies to determine which parts of their manufacturing process can be replaced by 3D printing.

Preparing future generations for digital manufacturing

As engineering and design become inextricably linked, hybrid tertiary courses will become increasingly prevalent for the next generation of engineers. Universities like Imperial College London and Penn State University have begun offering an Integrated Master’s Degree in Design Engineering and Master of Engineering in Additive Manufacturing and Design respectively. The HP-NTU Corporate Lab, which was announced last October, will also focus on developing educational curriculum on designing for additive manufacturing, covering areas like data management, security, user experience, and business models.

These courses fuse design thinking with engineering knowledge and practice to give graduates the skills required to contribute to the growth of digital manufacturing. In just a few years, they will be responsible for accelerating and normalizing digital manufacturing.

The landscape is shifting fast. If manufacturers are given access to the right tools and employees are inspired to find creative solutions to business challenges, there are countless ways to unlock new business opportunities.

—————————————————-

Rob Mesaros is VP and head of 3D Printing & Digital Manufacturing in HP Asia Pacific & Japan. He is responsible for driving HP’s mission to reinvent the way the world designs and manufactures with 3D printing technologies. He leads overall operations, as well as market and ecosystem expansion in the region.

Rob Mesaros is VP and head of 3D Printing & Digital Manufacturing in HP Asia Pacific & Japan. He is responsible for driving HP’s mission to reinvent the way the world designs and manufactures with 3D printing technologies. He leads overall operations, as well as market and ecosystem expansion in the region.

Leave a Comment

Want to join the discussion?Feel free to contribute!